When it comes to getting the best results from your table saw, few factors matter as much as the blade you choose and how well it’s maintained. A blade that is poorly chosen or dull can lead to burnt cuts, tear-out, wasted material, or worse — dangerous kick-back. This guide will walk you through how to select the right blade for your work, how to maintain it, and how proper blade care enhances accuracy, safety and the quality of your woodworking.

Why Blade Selection Matters

A high-quality table saw may cost several hundred dollars, but if you pair it with the wrong blade, you won’t realize its full potential. As one comprehensive guide puts it: “The right saw blade can be the difference between clean, glue-ready joints, and charred wood that smells like toasted marshmallows.” KM Tools

Important blade features include:

- Tooth count and geometry: more teeth generally create smoother finishes (such as for cross-cutting), fewer teeth promote faster cuts (such as ripping). KM Tools

- Kerf width (the thickness of the cut): full-kerf blades remove more material, thin-kerf blades can cause less waste and require less power. KM Tools

- Material and coating quality: carbide tipped, good quality alloys, and anti-heat-build up coatings can prolong life and maintain accuracy. KM Tools

Matching Blade to Cut Type

You’ll frequently hear about three categories of cuts: ripping (with the grain), cross-cutting (across the grain), and specialty cuts (dadoes, rabbets, bevels). Each has blade considerations:

- Rip cuts: Use a blade with fewer teeth (e.g., 24-30T) and large gullets to clear sawdust and cut efficiently. The faster feed helps when ripping large boards. KM Tools+1

- Cross-cuts: Use a blade with many fine teeth (e.g., 60-80T) to produce a clean surface with minimal tear-out. Slower feed, but superior finish. KM Tools

- Combination or general-purpose blades: These try to balance both ripping and cross-cutting. Not as optimized, but convenient for mixed tasks.

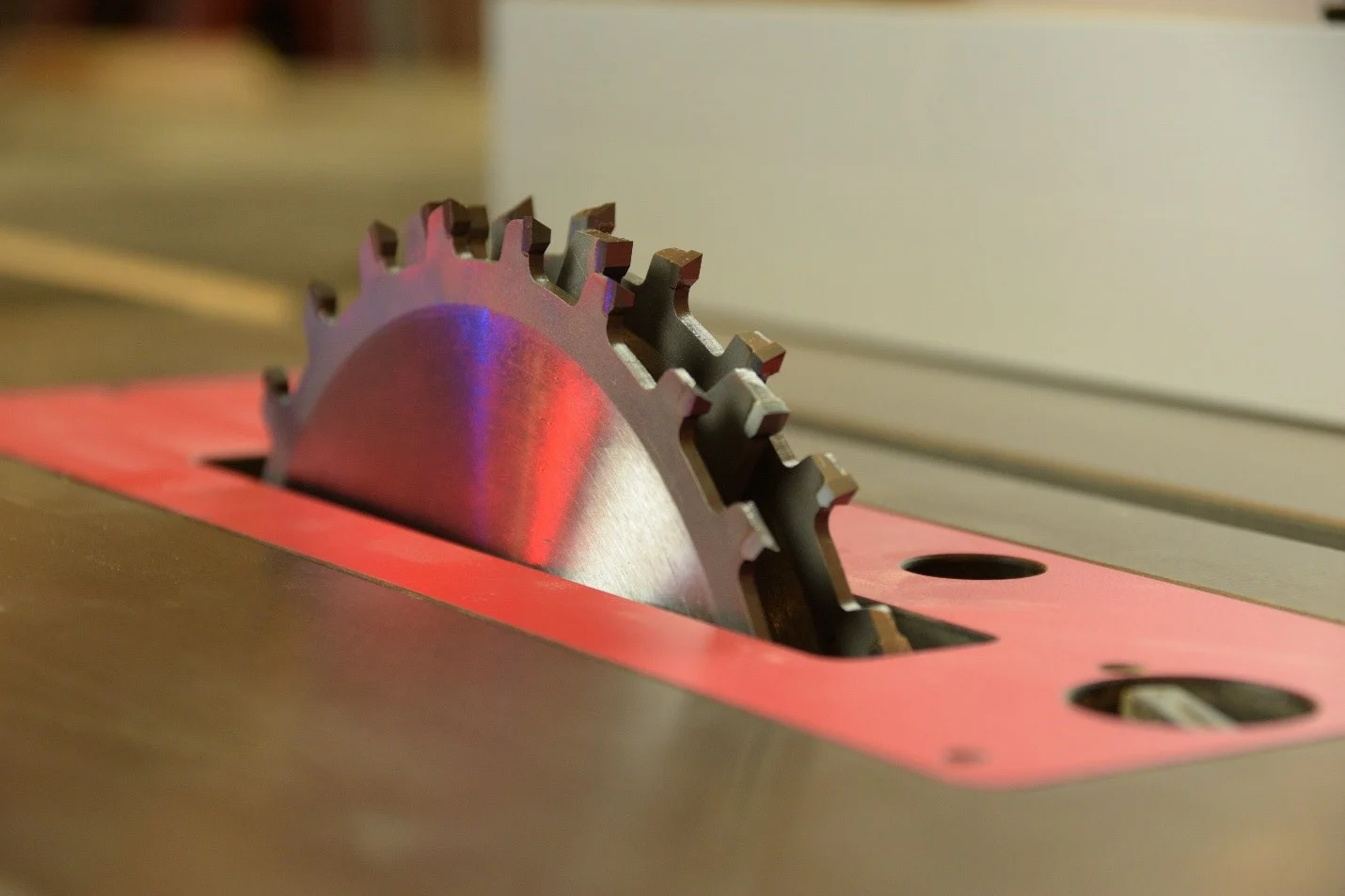

- Specialty blades: For dadoes and rabbets, stacked-dado sets or dedicated blades may be needed. Note that in some markets (e.g., Europe) dado sets are prohibited on table saws. Pro Tool Reviews+1

Blade Maintenance & Care

Having the right blade is only half the job — keeping it sharp and aligned is equally important.

- Cleaning: Resin, pitch, and burnt wood deposits degrade cutting performance and increase heat. Clean blades with appropriate solvent and remove buildup.

- Sharpening or replacing: A dull blade increases risk of tear-out, burning, and kick-back. It also forces slower feed rates and more effort.

- Check alignment: Ensure the blade is square to the table, the arbor is true, and the blade is mounted properly. Misalignment causes poor cuts and can be dangerous. Ask Jon Eakes

- Proper handling: Don’t touch teeth with bare hands, store blades flat or hanging, avoid dropping or damaging them, as a bent blade is dangerous.

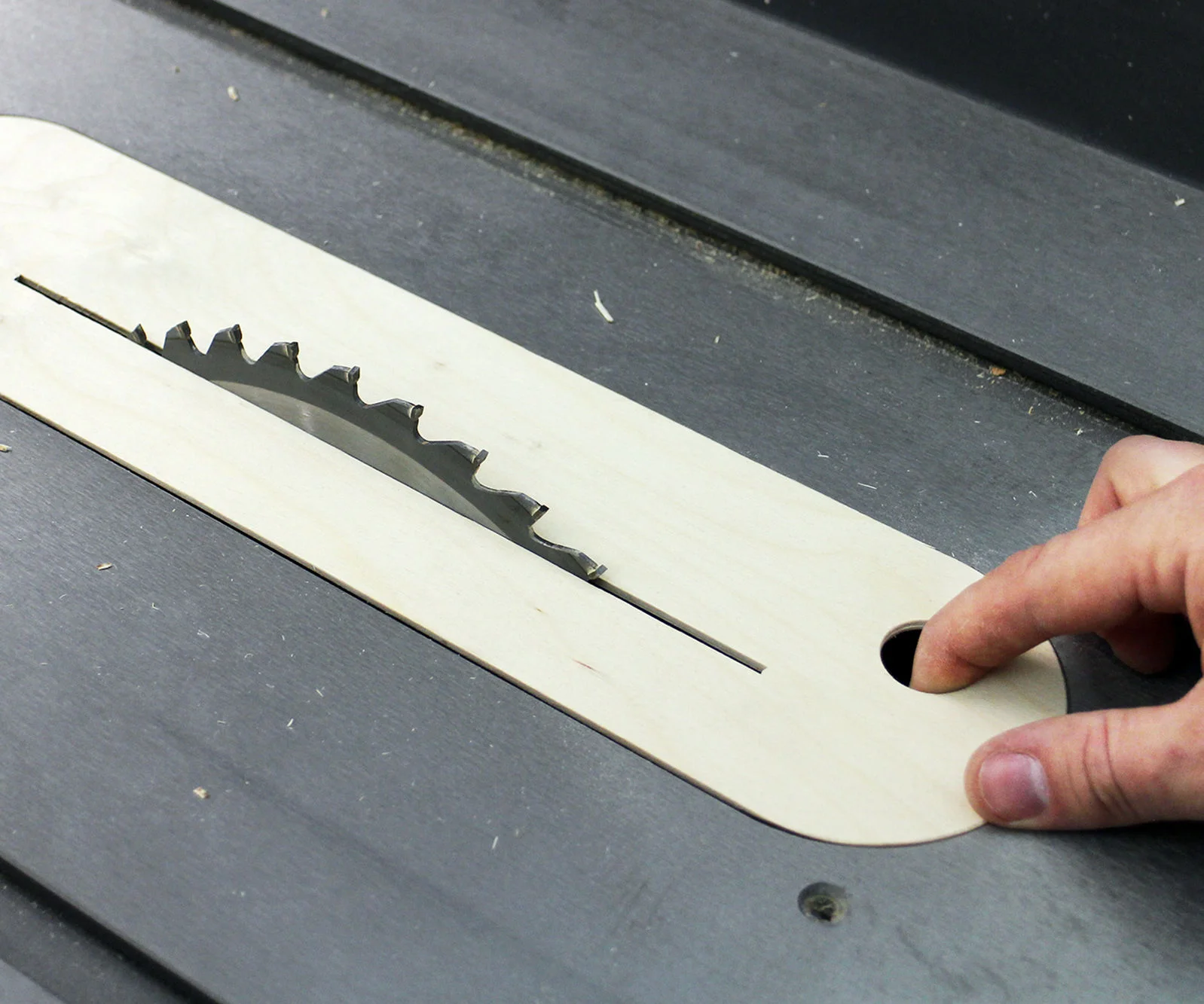

- Change height as needed: Use minimal blade height (just above the material) to reduce exposure, heat, and risk. Gosforth Handyman

Signs Your Blade Needs Attention

Watch for the following warning signals that your blade may not be up to the job:

- Burn marks on cut edges.

- Excessive tear-out or chipping.

- Difficulty feeding material (you’re pushing, not letting it pull through).

- Lots of vibration or wobble during cut.

- Cuts are not tracking straight or perpendicular.

Tips for Maximising Blade Life & Cut Quality

- Always match the blade to the material — e.g., plywood may need a blade designed to minimise tear-out, metal inserts may need a blade rated for non-wood.

- For large sheet goods, consider whether your saw is the right tool — some guides suggest that for the initial cut of a full sheet of plywood, a track saw or panel saw might be more secure. Pro Tool Reviews

- Use feather-boards, push-sticks, and hold-downs to keep work tight against the fence/table and reduce load on the blade and saw — this also improves cut quality. Wikipedia

- Make sure dust collection is working; dust build-up around the blade increases heat and dulling.

- Keep an eye on the blade’s “hook angle” and general geometry; when wear becomes excessive, performance drops off quickly.

Conclusion

Choosing the right blade and keeping it in top condition is a key part of getting the most out of your table saw. A quality blade well maintained can deliver perfect cuts, prolong tool life, reduce risk and make your woodworking much more pleasurable. By paying attention to tooth count, kerf width, material, maintenance and matching to the correct task, you’ll not only avoid headaches — you’ll produce better-looking, more accurate work and maintain a safer workshop environment.