This collection of woodworking terms will be an ongoing process and will be updated on a regular basis for the immediate future.

Woodworking terminology can be quite confusing to people just starting out, much like medical terminology to a layman. The good news is it’s a lot easier to understand.

Many of the sub-headings are links that will take you to a page with much more information about that particular topic.

ATB — Short for “Alternate Top Bevel” and refers to the way the teeth of a saw blade are shaped and set. The teeth are beveled inward from the outside edge of the blade, alternating left to right.

A variation is the HATB (High Alternate Top Bevel) that has a much steeper bevel than the ATB.

Bevel Cut — An angle cut made on a board. A common bevel cut in woodworking is a 45 degree bevel used to join two boards together for a right angle joint.

Biscuit Joint — A butt joint strengthened with a football shaped biscuit of wood. The biscuit is glued and placed in slots cut with a biscuit joiner. The glue causes the biscuit to swell, creating a secure joint.

Biscuit joints are used extensively in cabinetry to make face frames and join narrow boards together to make panels for doors and drawers.

Board foot — One square foot of lumber one inch thick. To figure how many board feet in a board, multiply the width by the length by the thickness in inches, then divide by 144.

A board that is 6 inches wide by 96 inches long by 3/4 inches thick is 3 board feet. 6 x 96 x .750 = 432 / 144 = 3.0 board feet.

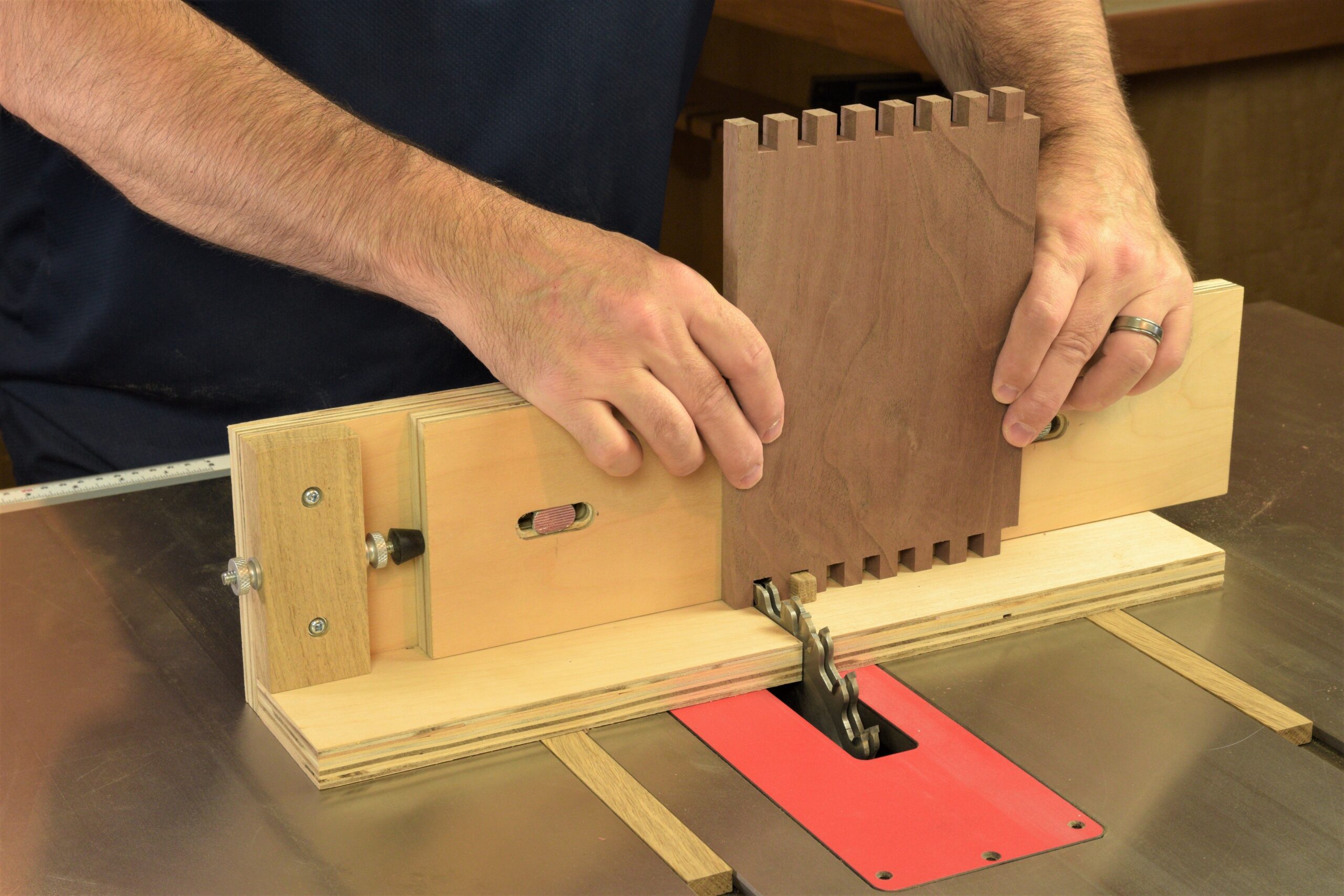

Box Joint — Also commonly called the finger joint, the box joint is made of interlocking fingers that form a right angle joint.

With the extra gluing surface provided by the interlocking fingers, and because it uses the straight grain of the wood, the box joint is also very strong. A woodworker with a fertile imagination will find many uses for this woodworking joint.

Butt Joint — A joint where to two boards are joined together end to end or end to side. Not much strength in this joint unless reinforced.

Cross cut — A saw cut that is made across the grain of the board.

End Splits — Lumber defect in which the ends of the board are split along the grain. Usually caused by uneven drying of the lumber.

Featherboard — A board with thin fingers on the end to hold stock against the fence of a table saw or router table for a more accurate cut. Can also be used to hold the stock down on the table when cutting dados or mouldings.

Hollow ground — A type of grind that forms a concave taper on one or both sides of a blade, leaving a very sharp but delicate cutting edge.

Kerf — Relates to the width of the cut of a saw blade. Because the saw teeth are set wider than the thickness of the blade material, the kerf is wider. May refer to either the blade kerf or to the cut left by the blade.

Kickback — Most common to the table saw, kickback occurs when the workpiece being cut is caught by the back of the blade and is thrown back at the operator, sometimes with disastrous results.

Common causes of kickback are when no splitter is used and the wood closes together behind the blade (usually induced by internal stresses) or when the workpiece is pinched between the rip fence and blade.

Mortise — The hole in which a tenon is inserted to complete a mortise and tenon joint. The mortise is usually rectangular in shape when applied to furniture, but also can be oval or even round like a dowel in the case of log (rustic) furniture.

Pocket holes — Pocket holes allow two pieces of wood to be joined together with a butt joint secured by screws. The pocket holes are drilled at a shallow angle into one piece of wood and then screws are driven though the holes into the other piece.

A pocket hole jig with a special drill bit is used to create the angled hole for the screws. Pocket holes are also used to assemble and make repairs on furniture and cabinetry when joints become loose or break.

Rabbet — A recess cut in the edge of a board. Used to form part of a joint, such as to set back panels flush with the main frame of a cabinet.

The drawing on the right shows a rabbet cut into one side of a two by four.

Stop block — A stop block is used when a woodworker wants to cut several pieces of stock the same length. It is usually attached to a fence at the desired distance from the blade and one end of the stock butts up against it.

It can be positioned in a number of ways such as using clamps, magnets and bolts. It can be made adjustable by attaching to a t-track or hinged to flip out of the way when not needed.

Tenon — The male end of a mortise and tenon joint. The tenon fits snuggly into the cavity of the mortise and when glued, makes one of the strongest joints in woodworking.